How Efficient Welding Assessment Improves Structural Integrity and Long Life

In the world of building and design, the value of welding examination can not be overemphasized, as it plays a critical role in making certain structural stability and prolonging the life-span of projects. By deploying a variety of sophisticated evaluation methods, such as ultrasonic and radiographic testing, specialists can determine defects that may jeopardize the dependability of a structure. The question continues to be: just how do these precise processes translate right into concrete benefits for resilience and security? Join the expedition of how effective welding inspections can change prospective susceptabilities into strengths, adding to the long-lasting success of buildings.

Value of Welding Evaluation

Ensuring the structural integrity and safety of welded buildings mandates extensive welding assessment procedures. Welding examination offers as a vital safeguard in the building and production markets, where the stamina and toughness of joints dramatically influence the total efficiency of structures.

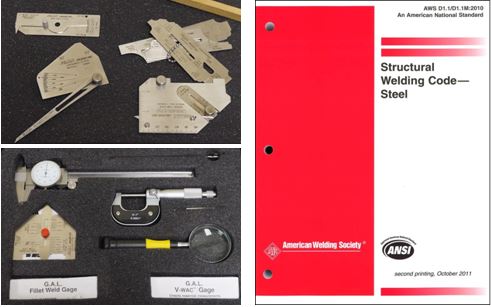

In addition to safety, welding inspection plays a vital role in top quality guarantee. By sticking to established criteria, inspections establish the uniformity of welds, making sure that each meets the desired toughness and visual demands. This consistency is essential not just for security however also for keeping the track record and reliability of producers and contractors. Additionally, regulative compliance is a substantial chauffeur of welding evaluation practices. Sector requirements and codes, such as those from the American Welding Society (AWS) or the International Company for Standardization (ISO), require adherence to rigorous guidelines, emphasizing the value of assessments in fulfilling these professional and lawful obligations.

Key Examination Techniques

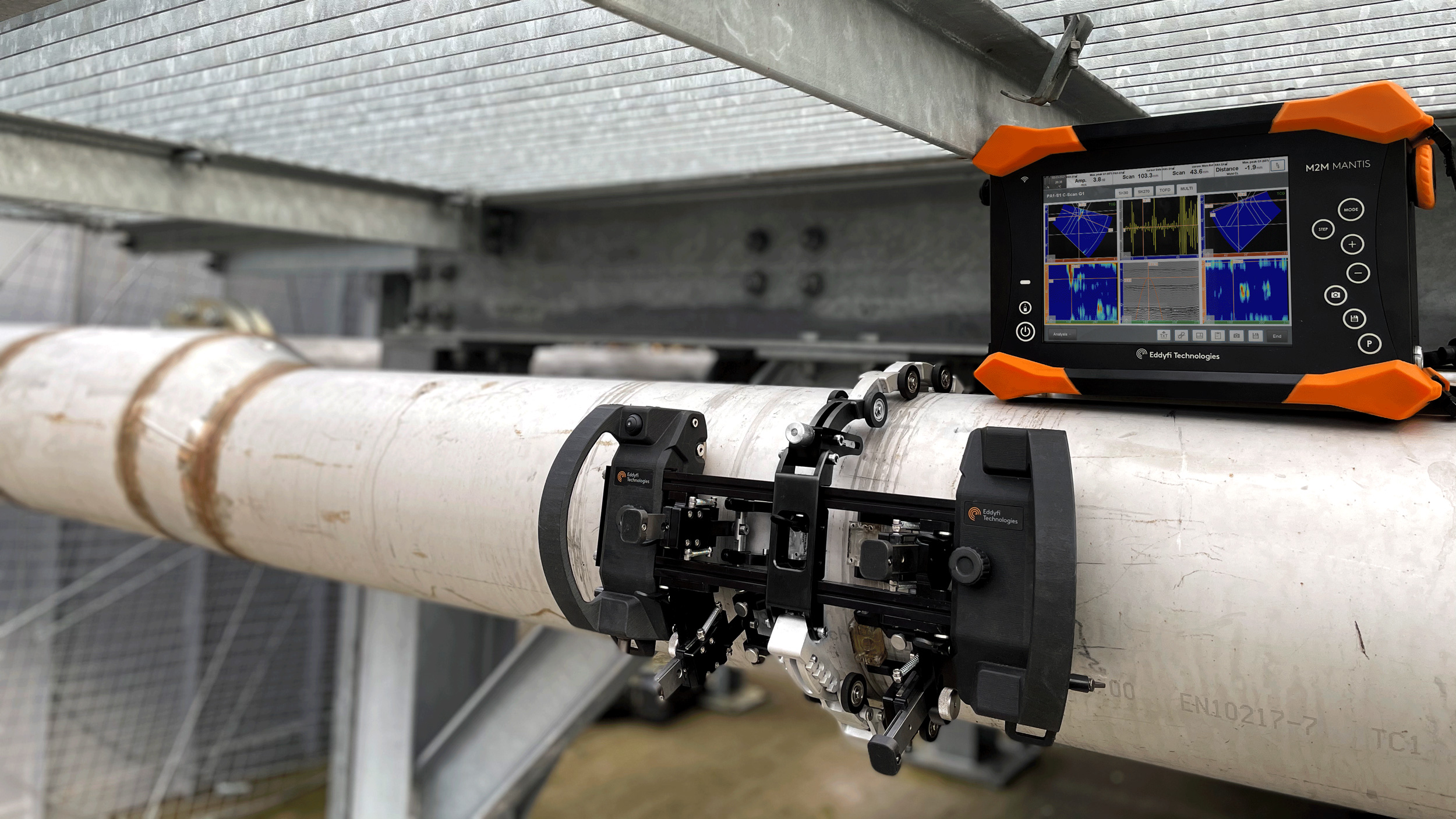

Ultrasonic Testing (UT) uses high-frequency acoustic waves to discover subsurface imperfections, offering accurate info about weld stability without creating any kind of damage. Radiographic Checking (RT), including X-rays or gamma rays, supplies an in-depth image of the weld's internal framework, exposing hidden imperfections. Magnetic Particle Checking (MPT) is one more non-destructive approach, especially reliable for detecting surface area and near-surface stoppages in ferromagnetic products.

Penetrant Testing (PT) entails the application of a liquid color to reveal surface-breaking problems, using a cost-efficient and uncomplicated option for non-porous products. Each strategy has its specific applications, strengths, and constraints, and commonly a combination of techniques is used to attain comprehensive evaluation results. Mastery of these methods improves the reliability and resilience of welded structures, lining up with safety and security and performance expectations.

Identifying Common Problems

Porosity, defined by gas pockets within the weld, lowers the weld's strength and resilience. Cracks, which can take place throughout or after welding, present significant dangers due to their prospective to circulate under tension.

Insufficient fusion, where the weld metal fails to bond completely with the base material, threatens the architectural integrity, resulting in weak joints. This additional hints flaw typically originates from insufficient warm input or incorrect welding method. Slag additions take place when non-metallic materials are entraped in the weld, jeopardizing its toughness and quality. These are typically an outcome of inadequate cleaning between weld passes or incorrect change use.

Determining these problems via precise examination techniques, such as visual exam, ultrasonic screening, or radiography, is critical. Addressing these problems guarantees weld top quality, eventually sustaining the structural integrity and safety of the constructed setting.

Enhancing Architectural Efficiency

Comprehending the significance of determining typical weld problems normally results in checking out methods for boosting structural efficiency. The fundamental method for boosting performance entails utilizing innovative welding strategies and materials that minimize defect occurrence. Utilizing high-grade filler materials and making certain proper heat control can considerably decrease issues such as porosity and fracturing, consequently improving the weld's honesty.

Including modern welding technologies, such as laser welding and friction stir welding, further enhances structural resilience. These strategies provide remarkable accuracy and minimized thermal distortion, straight affecting the sturdiness and strength of the bonded structures. Embracing automated welding systems can make certain regular and repeatable weld top quality, lessening human error.

Furthermore, implementing rigorous pre-weld and post-weld treatments is vital. Appropriate joint layout, surface preparation, and stress-relieving processes add to optimum weld efficiency. Conducting complete pre-weld evaluations enables very early discovery of prospective problems, helping with timely modifications before they compromise the structure.

Long-lasting Benefits of Inspection

With cautious evaluation techniques, company website the long-term benefits to structural honesty browse around here become significantly evident. Detailed and constant welding inspections play an important function in stopping structural failings by recognizing problems and variances early in the building process.

Moreover, normal assessments add to maintaining conformity with sector requirements and guidelines, thereby preventing monetary and lawful consequences. This adherence to top quality guarantee not just enhances the dependability of the framework but also promotes depend on among stakeholders, consisting of customers, designers, and regulatory bodies. The thorough documentation of evaluation outcomes offers as a useful source for future repair and maintenance efforts, helping with informed decision-making.

In addition, reliable examination practices support technology by including innovative modern technologies such as non-destructive testing and electronic imaging, which can boost accuracy and efficiency. This technical combination additionally emphasizes the dedication to excellence in architectural stability. Ultimately, buying careful welding assessments is a sensible approach that produces considerable long-lasting benefits, protecting both the physical and economic investment in infrastructure projects.

Verdict

Efficient welding evaluation plays an important role in enhancing architectural integrity and longevity by determining problems early in the construction procedure. Making use of methods such as aesthetic inspection, ultrasonic testing, and radiographic screening makes sure the discovery of problems like cracks and porosity that jeopardize weld stamina. Extensive inspections make certain compliance with industry requirements, therefore prolonging the life expectancy of structures, minimizing expensive fixings, and promoting stakeholder count on the dependability and safety and security of welded constructions.

In the realm of construction and design, the relevance of welding inspection can not be overemphasized, as it plays a critical role in making certain structural integrity and expanding the life-span of projects.Making certain the structural stability and safety and security of welded buildings mandates rigorous welding examination procedures.Building upon the relevance of welding evaluation in guarding architectural stability, recognizing the essential inspection methods ends up being critical for reliable implementation. Efficient welding examination includes a variety of methods designed to evaluate weld high quality, making certain conformity with strict design requirements - Welding Inspection Madison.Efficient welding evaluation plays a vital function in improving architectural honesty and longevity by identifying issues early in the construction procedure